“Hydraulics” means water in Greek and actually it is the examination of physical activity of water while moving and when it is still. Today, it’s not limited to water only but to the physical behavior of all liquids including hydraulic fluid. In the aviation industry, a hydraulic system isn’t new. In the earlier days, aircraft had hydraulic brake systems. With the development in the aircrafts, new systems with hydraulic power were introduced.

The hydraulic system application in aircraft is mission-critical. This is because the life of many peoples is on risk if anything goes wrong in an aircraft. Hence, the hydraulic systems of an airplane must be reliable a well as dependable. Additionally, those should be able to operate for extended periods without any failure risk.

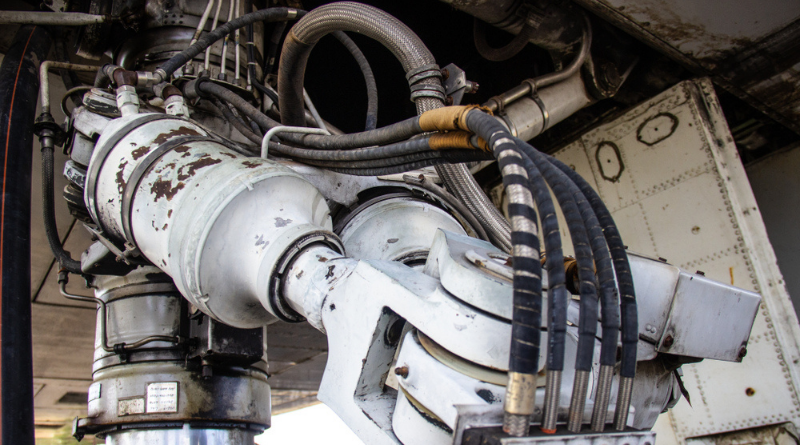

Hydraulic system is used in aircrafts. The hydraulic system uses pressurized hydraulic fluid to move the different components of an aircraft. The components include flight controls, landing gear and brakes.

Components of Aircraft Hydraulic System

1. Reservoir

Each hydraulic system has a reservoir to store the hydraulic fluid, a supply line to supply the fluid, a return line in which the fluid comes back to reservoir. The reservoir is pressured for constant flow of fluid through supply line. The pressure is maintained with bleed air from the engine.

2. Pump

Pump is another component that is used to pressurize hydraulic fluid. The pump is driven by the engine or is electrically operated. Hand pump can be provided if engine driven and electric pump is not available. While operating normally, the pump must be able to supply fluid at constant pressure.

3. Filters

Filters are another component used for removing any particles or impurities from the fluid as they can damage the hydraulic system. Filters can be installed on the supply line, return line or critical components. When the fluid enters the filter and moves out.

4. Valves

Valves control and regulate the flow of the fluid. Different types of valves can be used for different functions. There is a check valves that allows the fluid to flow only in one direction. The shutoff valve cuts off the fluid from the system during emergencies such leak, fire, pump fault, etc. The pressure reducing valve is used for decreasing pressure of fluid in particular line. The selector valve changes the direction of pressurized fluid by rotation of the valve based on which side the pressure of fluid is required.

5. Actuator

The actuator helps in converting hydraulic pressure into mechanical action. It can be connected to the primary or secondary flight controls, landing gear, brakes and the nose wheel steering.

6. Accumulator

The accumulator holds pressurized hydraulic fluid. A diaphragm separates the fluid and the activator. The accumulator provides fluids at constant pressure when the demand increases and low pressure. It is the last pressure source during emergencies such as pump failure or if pressure in the supply line decreases.

Working of Hydraulic System

The basic idea behind aviation hydraulics is using pressurized liquid for moving some parts of airplane from one location to another. The operating pressure in the hydraulic system is based on the size of aircraft and type of function being performed, and it ranges from few 100 pounds / square inch to over 5000 pounds /square inch particularly in jumbo jets or huge cargo planes.

The hydraulic system is actually based on the Pascal’s Law. As per Pascal Law, when pressure is applied to any liquid at any location in the enclosed system leads to equal pressure that is distributed everywhere within that system.

The process of hydraulic system in aircraft is easy. In this, a particular hydraulic system is activated by the pilot or a crew member with a switch or flight control device. The pump gets activated with this and pressurizes the system activating the motion of actuator. The actuator’s movement is directly transferred to the control surface or other device – such as brakes, landing gear, or perhaps a cargo ramp moving them into the desired position. For reverse movement, pressure is released from the system, and the opposite takes place.

Benefits of Aviation Hydraulics

Aircraft hydraulic system offers dependability and reliability. This is because the basic operating is simple, the number of moving parts is less and this leads to decrease in the risk of failure.

The response of hydraulic systems to control inputs is fast and effective. As the aeronautical flight is risky, it is important to have precise control of the aircraft for safety. When there is any critical condition in the flight, the pilot should be able to operate the flight control function regardless of whether the situation with take place or how long it will stay. This kind of functionality is offered by the aircraft hydraulic system.

The next benefit of hydraulic systems is that the hydraulic fluid isn’t prone to compression like the air compresses with change in the climate. This is a significant point to consider due to the dynamic pressure changes that take place as the aircraft decreases or increases the altitude. These changes don’t affect the fluid in the hydraulic system but may have an impact on similar systems using gas rather than a liquid.

Conclusion

Thus, hydraulic systems are highly reliable and have some unique benefits such as a power source, that includes power, ease and accuracy of control and faster response. In aircraft operations, these features are highly important and make hydraulic power vital for smooth and safe flight operations.