HYDRAULIC INTENSIFIER

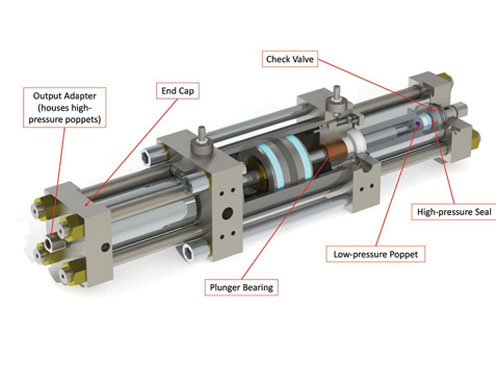

The CNG hydraulic intensifier is a compact assembly that consists of two gas cylinders separated by a hydraulic cylinder. There is a hydraulic piston that is placed at the center of the piston ride pushes the piston ride assembly back and forth. This drives the gas pistons at each end of the ride. The CNG intensifier uses two stages of compression to provide gas at pressure of as high as 4500 psi and suction pressure of as low as 300 psi. Oil that is pumped into the hydraulic cylinder supplies the power for moving the piston in compressed gas. Due to the action of gas pistons moving back and forth, the gas gets pulled in, compressed and discharged. Then the intake check valve passes gas into the cylinder and the discharge check valve passes gas out of the cylinder. The contamination of the gas is prevented with a set of seals at each end of the hydraulic cylinder. The CNG intensifier doesn’t allow any oil or contaminant into the gas that offers high fuel quality.

Advantages :

- Offer high quality fuel.

- Low maintenance costs.

- Improves environmental performance.

- Reduces green house gas emissions as compared to gasoline and diesel.

Inside the cylinder , there are pistons in each stage which reciprocates . The mechanical actuation is through a hydraulic pump driven by electric motor. The gas coming from the network,

it’s filtered, and then sucked into the chamber of the 1st stage, through two inputs respectively located at the top and at the bottom of the cylinder, inside of which it’s compressed by the reciprocating movement of the piston. The inlet liquid is filtered first to avoid small foreign bodies which can damage the cylinder. The compressed liquid exits from the cylinder at the discharge pressure through two outputs (one at the bottom and the other at the top) to enter the first heat exchanger to cool off the liquid . The liquid , compressed in the first cylinder, enters the second stage chamber to undergo the second compression.

From the cylinder, after having passed through the second heat exchanger liquid, it’s sent to for use at high pressure (200 - 250 bar). In the circuits of the liquid, on delivery of both stages, are mounted a pressure switch and a safety valve that will intervene whenever the threshold values of the set pressure is exceeded