Hydraulic jacks

Hydraulic jacks double and single acting type

Our hydraulic jacks and jacking equipment is designed by practical experience within the civil and construction industry, mainly used for heavy lifting, pre-loading, pre-stressing or lowering applications.

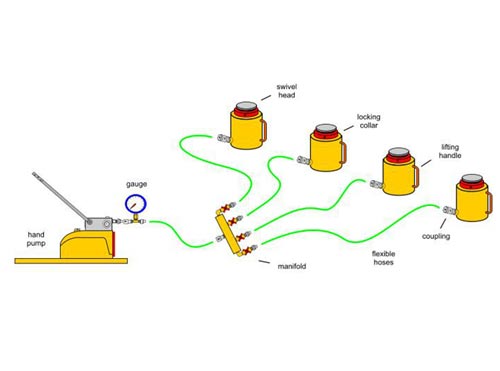

We provide a wide range of hydraulic jacking systems, from hand-operated or electric pumps with control manifolds and pressure gauges, as illustrated below, to the state of the art computerised control and monitoring equipment used for precise controlled hydraulic movement when carrying out major lifting projects, such as, bridge or house lifting operations or other large heavy structures which makes us the best hydraulic jack manufacturer.

Our range of low height hydraulic jacks vary from 5 to 520 tons capacity and are designed to work in the toughest environments to which this type of equipment is normally associated. Our hydraulic jacks are also equipped with locking collars to mechanically lock-off the ram after lifting and swivel heads to ensure that the load is transferred centrally through the jack.

As we are a hydraulic jack manufacturer, our custom made hydraulic jacking and monitoring equipment is specially designed and manufactured to suit many applications from preloading steelworks to temporary propping systems used for bridge jacking and bridge bearing replacement operations.

LHS products and installation services are available on a contract basis for small to major projects, or alternatively, customers can buy or hire our full range of specialist jacks depending on your requirements.

Range of hydraulic jacks consists of:

- Screwed ram jacks

- Low profile jacks

- Hollow ram Jacks / cylinders

- Stressing jacks

- Tensioning jacks

- Single acting spring return

- Single acting type

- Double acting jacks

- Long stroke jacks

- Both end clevis type jack

- Slip forming jack , Slipform jack

- Custom made manufactured hydraulic jacks

- Heavy Lifting Jack

- Industrial Jack

- Synchronized Jack

- Lifting Jack

- Electrical Operated Jack

- Tank Jack

- 12 MT Hydraulic Tank Jack

- 18 MT Hydraulic Tank Jack

- 25 MT Hydraulic Tank Jack

- Tankage Repairs Jack

- Tank Jacking System

- Tank Erection System

- Tank Construction System

- Tank Foundation Repair

- Heavy Lift Tank Jacking Equipment

- Tank Lift Jack

- Tank Construction Jack

- Tank Operated Jack

- Hydraulic Double Acting Jack

- Petroleum Storage Tank Jack

- Jack For Steel Storage Tank

- Jack For Fixed Roof Tank

- Jack For Floating Roof

- Hydraulic Power Pack

- 2 HP Hydraulic Power Pack

- 3 HP Hydraulic Power Pack

- 5 HP Hydraulic Power Pack

- 10 HP Hydraulic Power Pack

- 15 HP Hydraulic Power Pack

- 20 HP Hydraulic Power Pack

- 30 HP Hydraulic Power Pack

- 50 HP Hydraulic Power Pack

- Hand pump to operate jack

Manufacturing Facility permits us to manufacture the hydraulic jacks with specifications

- Capacity : upto 700 Bar and upto 1000 Ton

- Stroking distance: Upto 3 meters

- Speed : As per requirement upto 1 m/sec

- Temperature: −54°C to 260°C , in special cases we can go upto 500°C

- Mounting styles :[Front - intermediate - Rear ] : Flanges , Clevis , Shoe type ,swivel top, any customization available

- Honed tube Bore Size : upto 450 mm

- Piston Rod Size : upto 400 mm

- Piston Rod end : Threading / Pin / Step / Plane / ID threading / Swivel

- Piston Rod : Grounded and hard chrome plated and harden

- Material : Special Alloy steel with heat treatment , Stainless steel [SS] , Alloy steel , aluminium, titanium

- Inbuilt optional jack configurations: Both end cushioning , Non return valves , check valves , air vents , spring return ,pressure safety valve , and customization available

- Cylinder tubes :Plane with ports , customization available

- Seals: Being hydraulics manufacturer, we offer seals compatible with a range of temperatures and fluids and can help choose seal materials that meet application requirements

- All Components are CNC- VMV produced Subject to quantities